Understanding Chip Sealing:

A Practical Approach to Asphalt Maintenance

Asphalt surfaces are crucial for everything from highways to driveways, but over time, they can succumb to wear and tear. To extend their lifespan and maintain their functionality, many property owners and municipalities turn to a process known as chip sealing. This blog will delve into what chip sealing is, its benefits, the process involved, and why it might be the right choice for your pavement maintenance needs.

What is Chip Sealing?

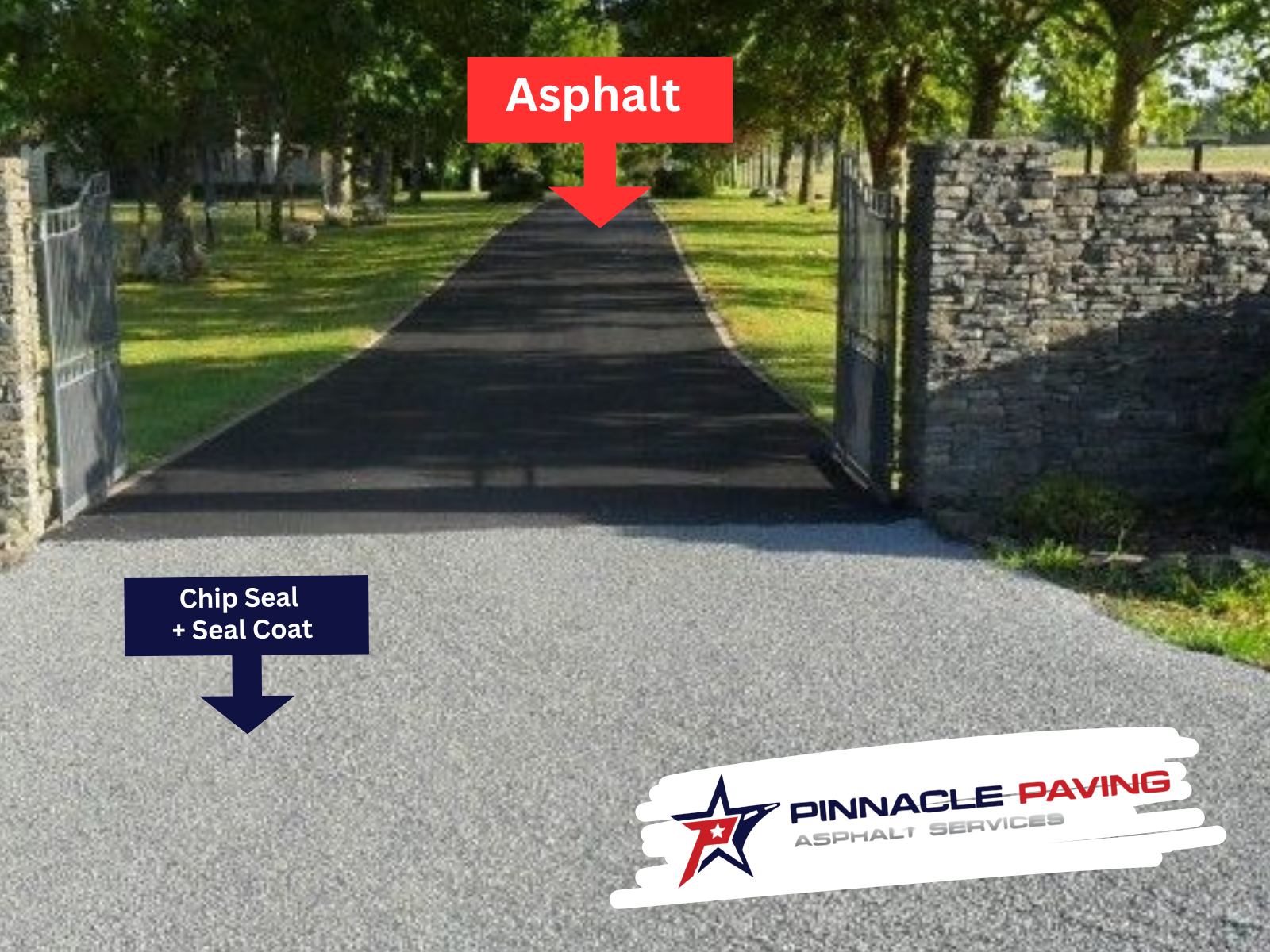

Chip sealing, also known as “surface treatment” or “tar and chip,” is a cost-effective method used to preserve and extend the life of asphalt surfaces. It involves applying a layer of hot liquid asphalt followed by a layer of crushed stone chips. The asphalt acts as a binder that holds the chips in place, creating a durable surface that enhances the road’s resilience.

The Benefits of Chip Sealing

Cost-Effective Maintenance

Chip sealing is significantly cheaper than a full asphalt overlay or reconstruction. It provides a new surface without the need for complete replacement, making it an attractive option for budget-conscious projects.

Extended Pavement Life

By sealing cracks and providing a new surface layer, chip sealing helps protect the underlying asphalt from further deterioration. This can add several years to the life of the pavement.

Improved Surface Texture

The application of stone chips improves traction and can reduce the risk of skidding, making it a safer option for high-traffic areas.

Minimized Water Damage

The sealing layer helps prevent water from penetrating the asphalt, which can reduce the risk of freeze-thaw damage and prolong the pavement’s durability.

Fast and Efficient Application

The chip sealing process is relatively quick, which means less downtime for roadways and driveways compared to other methods.

The Chip Sealing Process

Surface Preparation

Before chip sealing, the existing asphalt surface must be cleaned and prepared. This involves removing debris, loose material, and addressing any existing cracks or potholes.

Application of Liquid Asphalt

A layer of hot liquid asphalt is applied to the prepared surface. This acts as a binding agent for the stone chips and ensures they adhere properly.

Spreading the Chips

Immediately after the asphalt is applied, a layer of crushed stone chips is spread over the surface. These chips are usually spread using a specialized machine to ensure even coverage.

Rolling and Compaction

Once the chips are spread, a roller is used to press them into the asphalt, ensuring a tight bond and proper embedment. This step helps to reduce the loose stone chips that can create a mess or be a hazard to drivers.

Curing Time

After the application, the surface needs time to cure. During this period, traffic should be minimized to allow the asphalt to set and the chips to fully adhere.

Final Cleanup

Any loose chips that didn’t adhere during the rolling process are swept up. This step ensures a clean and finished appearance for the newly treated surface.

When to Consider Chip Sealing

Chip sealing is ideal for roads and driveways that are structurally sound but have started to show signs of wear, such as surface cracks or minor raveling. It’s not recommended for surfaces with severe damage or structural issues, as those conditions may require more extensive repairs or a complete resurfacing.

For municipal projects, chip sealing can be a practical way to manage large networks of roads economically. Homeowners with long driveways or private roads can also benefit from the cost savings and enhanced durability provided by this method.

Chip sealing offers a practical and economical solution for maintaining and extending the life of asphalt surfaces. With its cost-effectiveness, durability, and relatively quick application, it’s no wonder that it’s a popular choice for both public and private pavement maintenance. If your asphalt surfaces are showing signs of age but are otherwise in good condition, chip sealing could be the ideal method to restore their functionality and appearance.

Why Choose Pinnacle Paving Asphalt Services?

Experience and Expertise: Pinnacle Paving Asphalt Services has a proven track record in sealcoating. As an experienced company, we have the knowledge and skills to handle various types of asphalt surfaces and conditions. Ask us for references or examples of our work.

Quality of Materials: We only use the highest-quality sealants to ensure better protection and durability. Avoid companies that use low-quality materials, as they may not provide the same level of protection or longevity.

Turn-Key Process: We guarantee a convenient and hassle-free experience.

Request an Estimate: Schedule an appointment for a free estimate. Our estimate will Request a detailed estimate that outline all of the costs associated with the project, including preparation, sealcoating, and any additional services. A clear estimate helps avoid unexpected expenses and ensures that you understand the scope of work.

Give us a call today to schedule an appointment for a free estimate.